CAPABILITY

NEWS CENTER

APPLICATIONS

SOLUTIONS

SUPPORT

TOUCHPANEL BLOG

CONTACT US

Capacitive vs. Resistive Touch Screen Selection Strategies: A Guide for Industrial, Medical, and Automotive Applications

10 Sep. 2025

Introduction: The Interplay of Technology and Market

Touch technology has become a pivotal force in modern life, with touch panels ubiquitous from smartphones to automotive navigation systems. However, within this fiercely competitive market, two primary technological approaches—capacitive and resistive touch panels—are engaged in a decisive battle for market dominance.

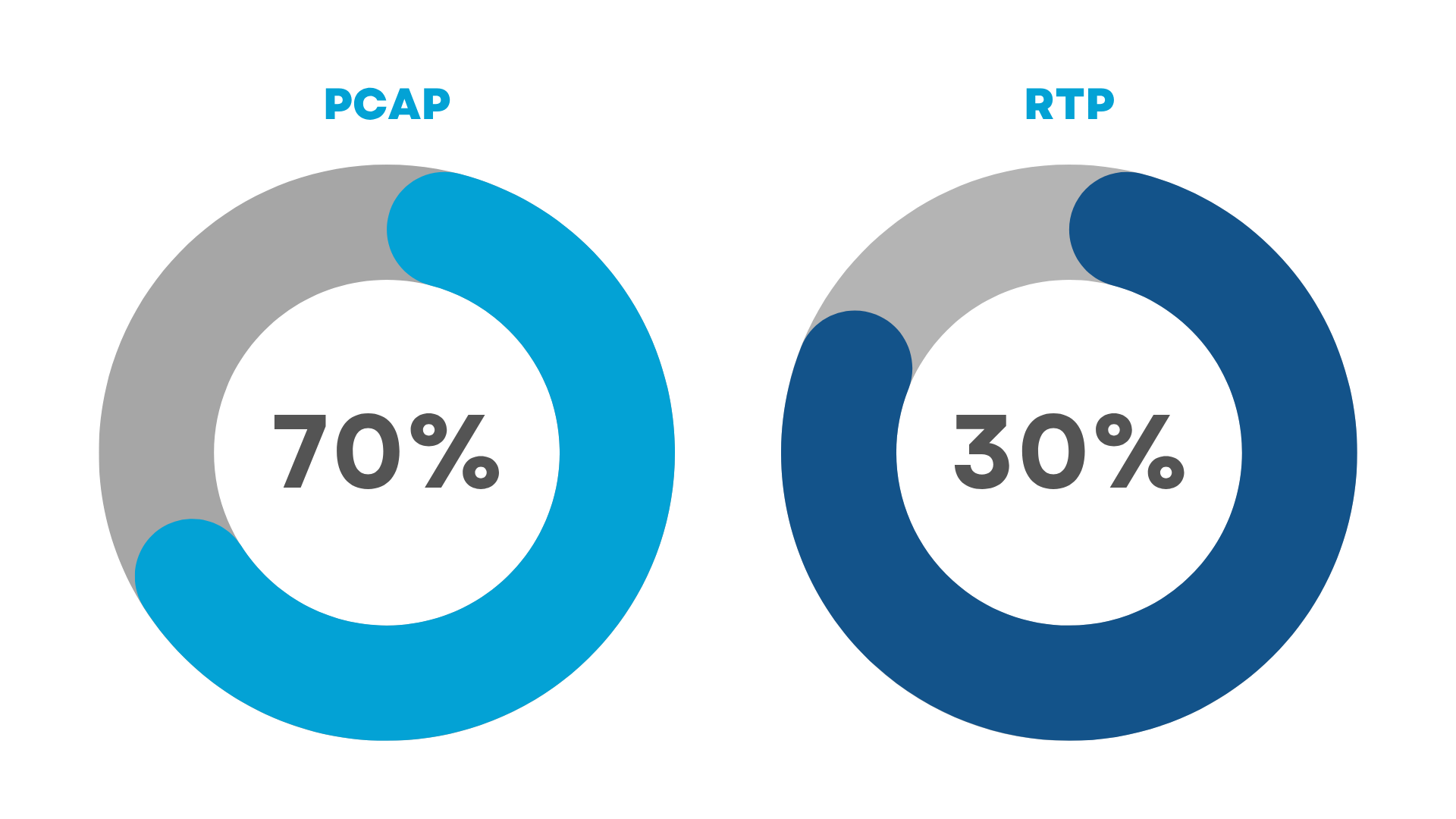

Leveraging their superior sensitivity and multi-touch capabilities, capacitive touchscreens firmly hold the leading position in the consumer electronics sector. Conversely, resistive touch panels, known for their robust durability and interference resistance, dominate the industrial and medical equipment markets. Market analysis forecasts the global touch panel market size to exceed $85 billion by 2025, with capacitive panels accounting for over 70% of the market share. This interplay between technology and market dynamics presents new challenges for companies regarding technology selection and strategic planning.

As touch technology rapidly evolves, businesses must thoroughly understand the performance distinctions between these two major technologies, as well as the underlying market trends and application scenarios. This article will provide an in-depth analysis covering technical principles, performance comparisons, application scenarios, and market insights across various dimensions, empowering your business to make informed decisions regarding touch technology.

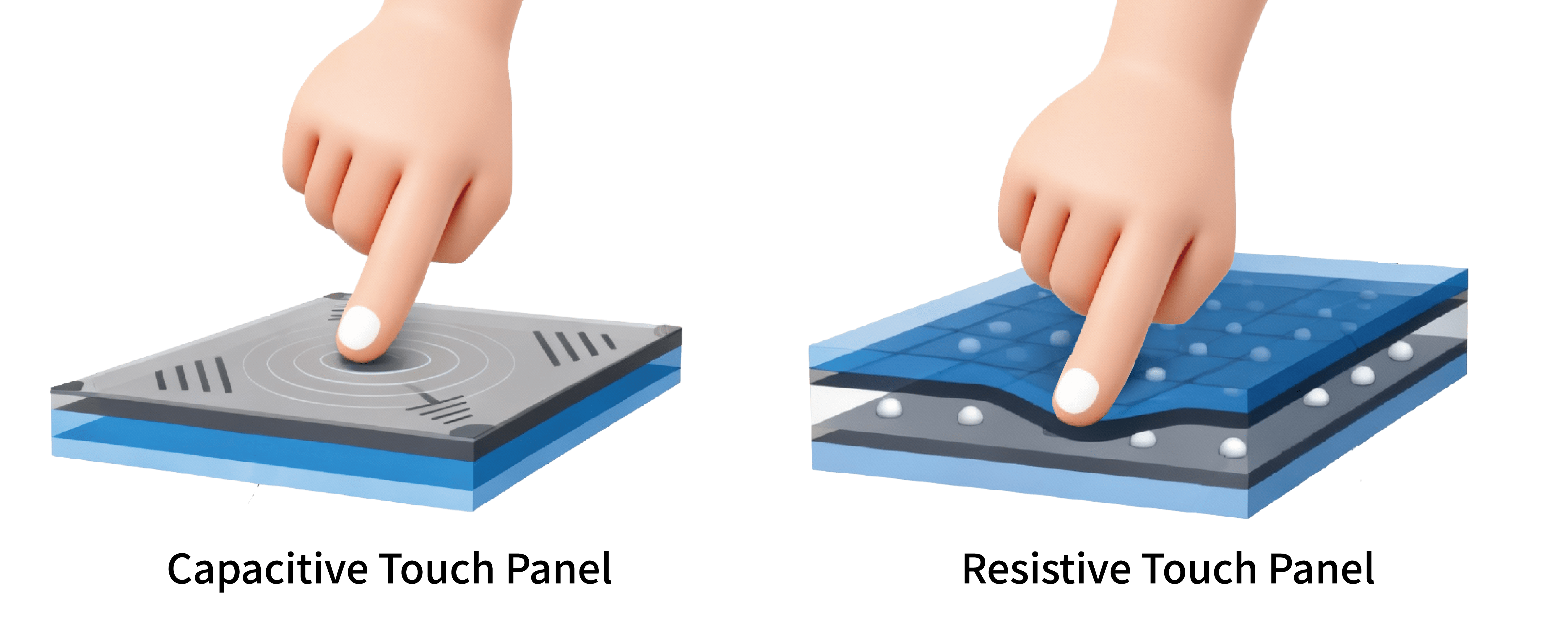

The core of capacitive touch technology lies in electric field sensing. When a finger contacts the panel, a slight charge alters the electric field distribution. Sensors swiftly capture this change and precisely calculate the touch location. This technology supports multi-touch and boasts extremely fast response times and precise control, making it excel in applications requiring high agility. It is currently the preferred solution for smartphones and high-end automotive infotainment systems in the market.

In contrast, resistive touch technology relies on physical pressure for operation. Two conductive layers make contact under pressure, forming a closed circuit that determines the touch location. This technology offers robust interference resistance and operates stably even in harsh environments such as high humidity or temperature. This makes it a reliable choice for industrial equipment and medical instruments. For instance, in chemical plants or mining facilities, resistive panels effectively withstand dust, chemicals, and high temperatures, ensuring stable and uninterrupted operations.

The historical development of these technologies is also noteworthy. Capacitive technology rapidly gained widespread adoption as the standard for consumer electronics after Apple introduced the first iPhone in 2007. Although resistive technology has gradually been superseded in the consumer market, it maintains stable demand in the industrial and medical sectors. This clear differentiation in technical positioning directly influences strategic choices for businesses across various application scenarios.

▶ Capacitive Panels

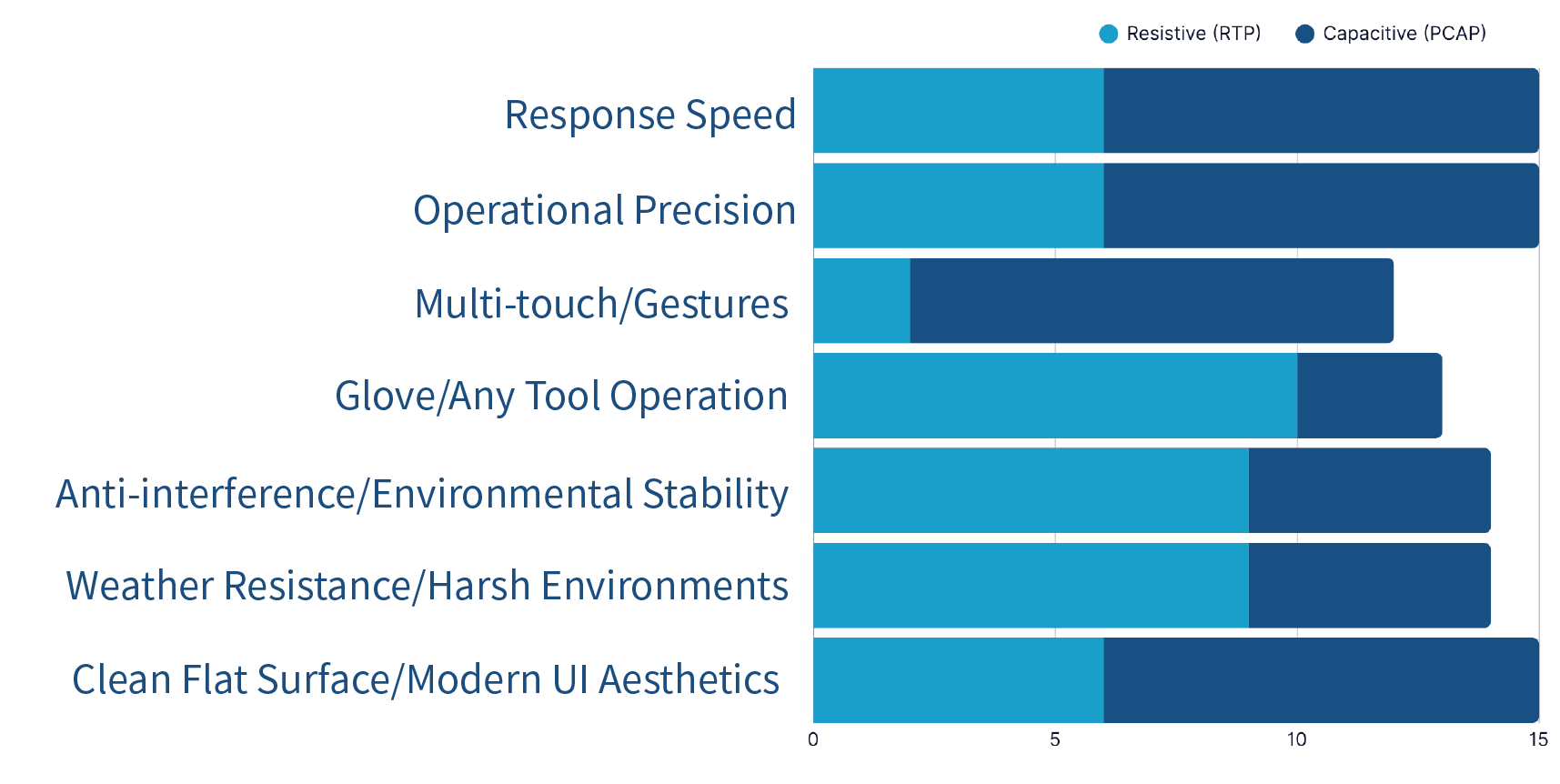

Offer near real-time response, perfectly suited for high-precision applications such as aerospace flight simulators. When pilots perform simulated operations, capacitive panels swiftly respond to commands, ensuring seamless and precise control. This characteristic also positions them as a core component in high-end consumer electronics, exemplified by the multi-touch functionality of smartphones.

▶ Resistive Panels

Being pressure-triggered, exhibit a slightly slower response time. However, their exceptional stability makes them highly suitable for industrial control systems and similar environments. In applications demanding consistent input, resistive panels maintain reliable performance. For instance, industrial control panels require a long-term stable operating environment, and the inherent reliability of resistive technology makes it a preferred choice.

▶ Capacitive Panels

Can recognize subtle user movements, making them ideal for gesture control and high-resolution displays. For example, touchscreens in operating rooms require physicians to precisely zoom in on images or fine-tune data, and capacitive panels provide a highly detailed and intuitive operational experience.

▶ Resistive Panels

Due to their pressure-activated nature, offer less fluidity in operation compared to capacitive panels. Nevertheless, for instruments and equipment in industrial and medical settings, the press-activated operation often aligns better with the required interactive experience.

▶ Capacitive Panels

Offer scratch resistance but are susceptible to interference from water and oil.

▶ Resistive Panels

Operate stably in harsh environments, making them an ideal choice for factories and outdoor equipment. For example, in muddy or wet conditions, resistive panels effectively prevent environmental factors from interfering with operations, ensuring consistent performance.

Industrial scenarios demand extremely high levels of stability and durability. Resistive touch panels, with their excellent EMI resistance, can adapt to harsh conditions such as high temperatures and humidity, making them the preferred choice for chemical plants and mining equipment. However, capacitive panels are also emerging in intelligent industrial equipment, offering multi-touch and high-precision operation. For instance, in the control panels of precision instruments, capacitive technology provides a more intuitive and efficient operating experience.

The medical sector has unique demands that position resistive panels as crucial in operating rooms and emergency departments, primarily due to their support for gloved operation and frequent cleaning. Capacitive panels, on the other hand, are more commonly used in high-end diagnostic instruments, offering intuitive operation and easy-to-clean surfaces. For example, the control systems of smart hospital beds adopt capacitive technology, significantly enhancing the operational efficiency of medical professionals.

In applications like railway trains and mining vehicles, resistive panels are an ideal choice for harsh environments due to their ruggedness and EMI resistance. Concurrently, capacitive panels, with their high-resolution displays and multi-touch capabilities, are increasingly being adopted in high-end intelligent equipment. For example, in the smart control interfaces of mining vehicles, capacitive panels help operators more precisely adjust parameters or monitor equipment operation.

Resistive vs Capacitive Touch Screen Performance Analysis

The market advantages of capacitive touch panels are clear, making them the inevitable choice for high-performance scenarios. Resistive touch panels, conversely, stand out for their exceptional stability and durability, making them an ideal solution for harsh environments. Higgstec, as a leader in touch technology, offers comprehensive solutions encompassing multi-point capacitive and 5-wire resistive technologies, helping businesses effectively mitigate risks in their technology selection.

For example, Higgstec’s capacitive panels integrate waterproof and dustproof designs, significantly improving the environmental limitations of capacitive technology, making them highly suitable for automation equipment. Furthermore, its multi-point resistive technology breaks through the limitations of traditional resistive technology, supporting more complex operational requirements.

The competition between capacitive and resistive touch technologies clearly reflects the diverse demands of the market. Looking ahead, we anticipate a convergence of these two technologies, offering more comprehensive solutions. For instance, combining the sensitivity of capacitive technology with the stability of resistive technology will meet the needs of a broader range of application scenarios.

Higgstec, with its continuous innovation capabilities, is leading the next transformation in touch technology, helping businesses maintain a competitive edge in diverse markets. Our technical team is dedicated to developing more efficient and stable touch solutions, assisting clients in achieving a comprehensive enhancement of product value.

Capacitive Touch Panels sense changes in the electric field caused by human touch, offering fast response times, multi-touch support, and high resolution and precision. Resistive Touch Screens, on the other hand, rely on pressure sensing, providing excellent EMI resistance, glove or wet-hand operation, and high stability, making them particularly suitable for industrial control and harsh environment applications.

Commonly found in smartphones, high-end automotive infotainment systems, precision medical equipment (e.g., smart hospital bed control interfaces), instrument control panels, and Human-Machine Interfaces (HMIs) requiring multi-point gesture operation and high visibility.

Primarily used in industrial control systems, HMI, protective operator stations in chemical plants, mining equipment, operating room control consoles, and large engineering and mining vehicles. They are also well-suited for environments with high electromagnetic interference, dust, oil, or where thick gloves are worn.

If the priority is smooth operation, gesture zooming, multi-touch, visual experience, and high-resolution interfaces, capacitive technology is advisable. If durability, noise immunity, glove operation, stability in harsh or outdoor environments, and cost control are primary considerations, then resistive touch panels are more suitable. Technology selection can also be evaluated based on the industry (medical, automotive, industrial, mining).

Yes. The market is progressively exploring hybrid or integrated touch solutions (Hybrid Capacitive-Resistive Solutions) that combine the high sensitivity of capacitive with the interference resistance of resistive technology. This aims to meet the consistent operational demands across multiple scenarios in Industry 4.0, HMI upgrades, smart medical, and in-vehicle applications.

For more technical details and customized solutions, please contact Higgstec.

Our professional team will provide you with the most precise support and service