CAPABILITY

NEWS CENTER

APPLICATIONS

SOLUTIONS

SUPPORT

TOUCHPANEL BLOG

CONTACT US

Elevating Industrial Touchscreen Quality: European Supply Chain & Tech Advancement Case Study

07 Jan. 2026

In industrial equipment applications, the stability and accuracy of touch panels are critical. For manufacturers operating across Europe’s variable climates, weather resistance, anti-interference performance, and supply chain stability are decisive factors that determine product success.

One of our European partners (anonymous case), a leading brand in the industrial equipment sector, recently faced operational bottlenecks due to touch panel quality and supply chain challenges. We addressed their core pain points with a systematic solution that not only solved the immediate issues but also laid a solid foundation for long-term collaboration.

Before our engagement, this European client—focused on highly reliable equipment—was being held back by the performance of its touch panels.

Their problems fell into two main areas

Persistent quality issues and an unstable supply chain structure

For industrial-grade applications, touch panel reliability is paramount. However, the client’s existing products frequently malfunctioned, directly eroding end-user trust.

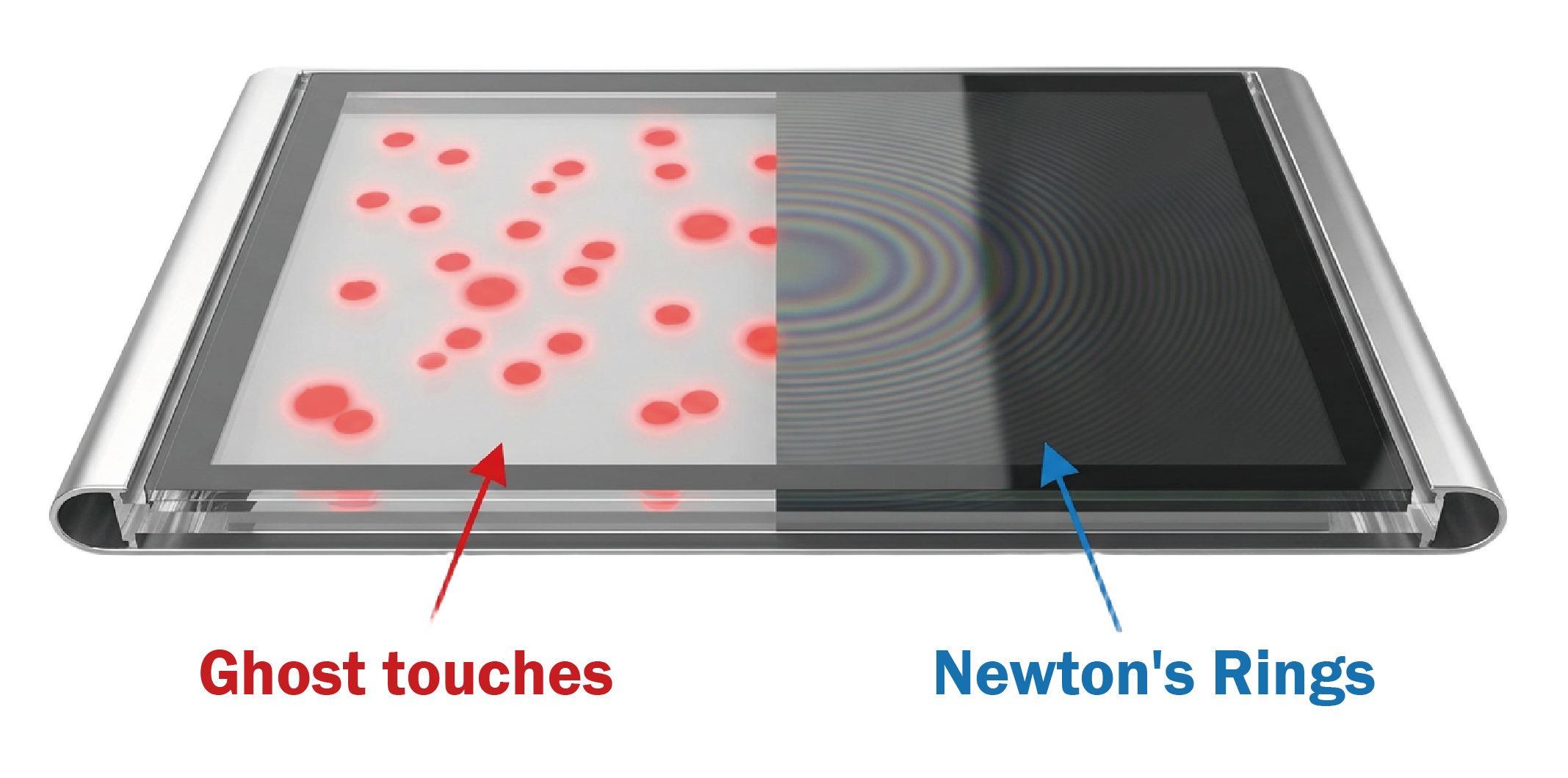

Touch Failure and False Triggers: They received field reports of sluggish response, poor touch accuracy, and even “ghost touches” caused by electromagnetic interference—serious safety concerns in precision industrial operations.

Optical Defects Undermining Professional Image: “Newton’s rings” (air-gap interference) and “rainbow patterns” (often from polarizer interference) appeared on screens. While not directly functional issues, they degraded the premium look and feel of high-end equipment, increasing after-sales costs and potentially damaging market reputation.

In seeking remedies for the quality issues, the client was caught in a no-win dilemma: continuing with flawed parts would keep damaging their brand; switching suppliers abruptly could stall production and block deliveries—a massive risk. The supply chain’s uncertainty was a ticking time bomb that put operations in constant jeopardy.

We understood the client didn’t need a passive parts supplier, but a proactive technology partner who solves problems and co-plans for the future.

With urgent issues at hand, our top priority was to resolve pain points quickly at the technical root. We formed a project task force and held multiple deep-dive engineering sessions with the client’s team, delivering a targeted upgrade plan.

Optical Bonding Process Reinvention

To eliminate Newton’s rings and rainbow patterns (caused by air gaps between layers), we adopted full optical bonding, seamlessly laminating the touch sensor, display, and cover glass with optically clear adhesive (OCA). This significantly reduces optical interference and boosts contrast and outdoor readability (with trade-offs in cost and thickness).

Customized Touch Firmware Tuning

Industrial environments often require operation with gloves or wet hands. We optimized the touch IC algorithms, enhancing noise suppression and signal discrimination to ensure precise performance under harsh conditions.

Industrial-Grade Materials

We selected weather-resistant materials qualified by thermal cycling (-40°C to 85°C, per latest IEC references) and damp heat tests to withstand temperature and humidity swings—also factoring in green sustainability.

| Technical Approach | Issue Addressed | Technical Spec | Expected Outcome |

|---|---|---|---|

| Full Optical Bonding | Newton’s rings, rainbow patterns | Seamless lamination with OCA | Reduced optical interference; higher contrast |

| Touch FW Tuning | Glove/wet-hand operation | Optimized touch IC algorithms | Stronger noise suppression and accuracy |

| Industrial Materials | Insufficient weatherability | -40°C to 85°C temperature endurance | Withstands temp/humidity; IEC compliant |

We believe concrete test data is the cornerstone of business trust. After finalizing the technical plan, we produced high-quality samples and ran a suite of validation tests exceeding industry norms—inviting the client to witness the process.

EMC Stress Testing

In a professional anechoic chamber, we simulated high-intensity electromagnetic environments to validate anti-interference performance.

Environmental Reliability Tests

Using temperature-humidity chambers, we conducted extended thermal shock (-20°C to 70°C) and high-temp/high-humidity (e.g., 60°C/90% RH) testing to ensure long-term reliability under extreme climates.

User Scenario Simulation

Demonstrated optimized performance with wet hands and gloves.

These validation steps, grounded in data and evidence,

turned our technical commitments into assets the client can trust,

and built a solid foundation for long-term cooperation.

Solving the immediate problem was only the first step. A truly reliable partner must plan for the client’s future. We proposed a long-term supply chain management plan to turn risk into a competitive advantage.

Short-Term Goal (Supply Stabilization)

Prioritize the most urgent touch panel project to get high-quality products onto the line immediately, stabilize deliveries, and put the client’s business back on track.

Mid-Term Planning (Portfolio Expansion)

Building on the first project’s success, we engaged the client’s product teams to understand future roadmaps. Whether additional sizes or more complex PCAP projects, we pre-invested in technical reserves and development so we could act as an extension of their innovation capacity.

Long-Term Layout (Risk Management)

To address global supply uncertainties, we established a comprehensive risk management mechanism:

Alternative Material Matrix: For all critical components (e.g., driver ICs, glass substrates), we pre-qualified at least two alternative sources and documented them. If a primary source fails, we switch seamlessly to avoid production interruptions.

EOL (End-of-Life) Alerts: We closely track component lifecycle status. If EOL risk arises, we notify the client 6–12 months in advance and initiate replacement introduction plans, providing ample response time.

Version Control and Traceability: We rigorously manage hardware and firmware changes to ensure consistency and traceability throughout the product lifecycle.

The core value we delivered to the client can be summed up in one sentence

Their head of procurement told us

That peace of mind comes from a stable, reliable, and resilient supply chain we built together. The same stability is reflected in product quality—we effectively resolved long-standing pain points, replacing frequent complaints with positive end‑user feedback and reinforcing the client’s market leadership.

Underpinning all of this is a systematic project process. From requirement definition to mass production, clear steps shortened development, controlled risk, and enabled the client’s team to refocus precious resources on core business innovation.

If your products face challenges with touch technology or supply chain stability, we’re ready to apply our expertise and hands-on experience to deliver an end‑to‑end solution—from spec definition and product development to long-term stable supply.

Touch panels must deliver weather resistance, anti-interference capability, and a stable supply chain to operate reliably across Europe’s variable climates—preventing quality issues from harming brand image and safety.

Typical issues include touch failure, false touches (e.g., ghost touches), and optical defects like Newton’s rings and rainbow patterns. These undermine operational precision and the professional image of high-end equipment.

Use full optical bonding to eliminate Newton’s rings and rainbow patterns, and apply customized touch firmware tuning to enhance noise suppression and recognition for stable operation in industrial environments.

Conduct EMC stress tests, environmental reliability tests, and user scenario simulations, providing concrete data to ensure long-term reliability under extreme climate and operating conditions.

Establish an alternative material matrix, EOL alert system, and version control to ensure component diversity and traceability—reducing supply chain risks.

By combining technical upgrades with supply chain resilience, we resolved quality and supply issues while enhancing market competitiveness, enabling clients to operate steadily amid external changes and focus on innovation.

For more technical details and customized solutions, please contact Higgstec.

Our professional team will provide you with the most precise support and service